Heat Management Landed 3 new Purchase Orders During the Summer of 2024!

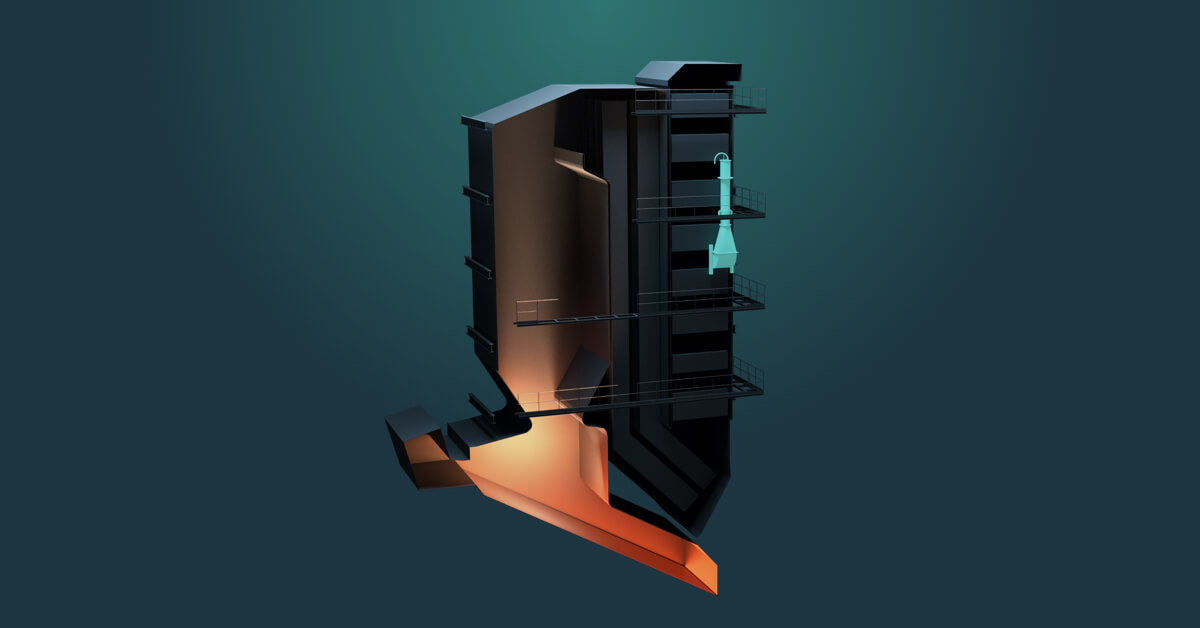

Introduction During the summer vacation, we have kept ourselves busy! Our salespeople and project teams have worked cleverly during the warmer months, bringing in more exciting opportunities. This growth in our future references will allow us to expand as a company and keep adding value to both new and recurring customers who explore the rest of our solutions portfolio. The following purchase orders have come through this summer: High Impact Sootblowing System (HISS®) July: A pulp and paper mill in Brazil Carryover Early Warning System July: A pulp and paper mill in Sweden. A recurring customer who also has HISS® Infrasound cleaning August: A Waste-to-Energy plant in Germany, Steinmüller Engineering provides another infrasound cleaner, which will mark the end-customer’s fifth Infrasound cleaner. Brazil Our new Brazilian customer ordered HISS® in late July. This second HISS® project in Brazil will be an essential reference for Heat Management in the South American market. The project's goal is to save steam for the [...]