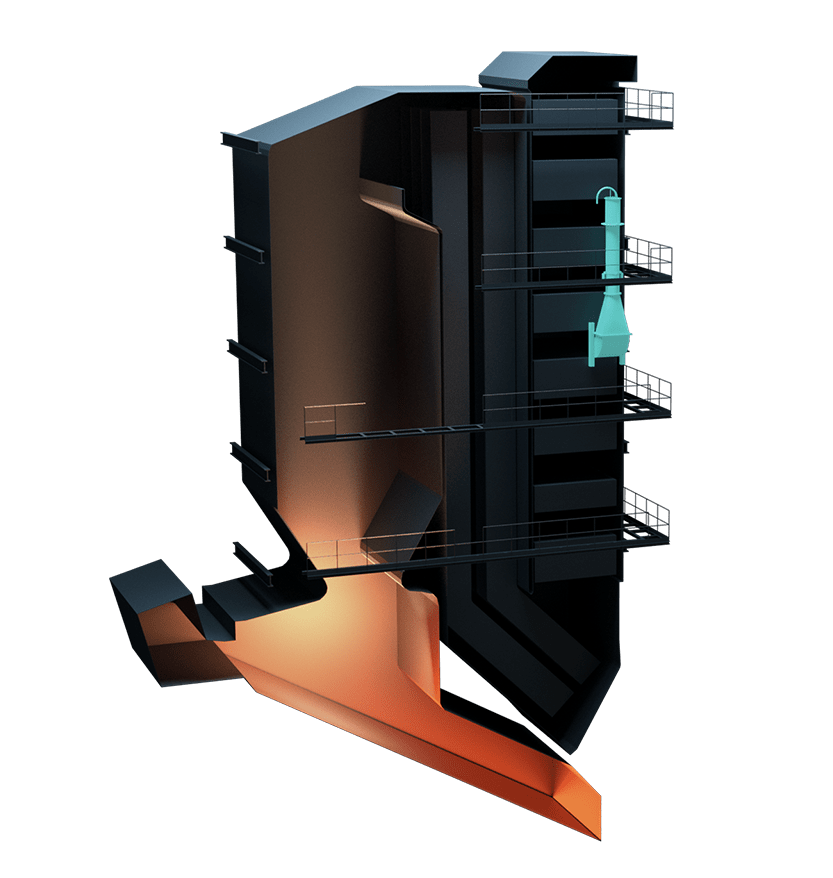

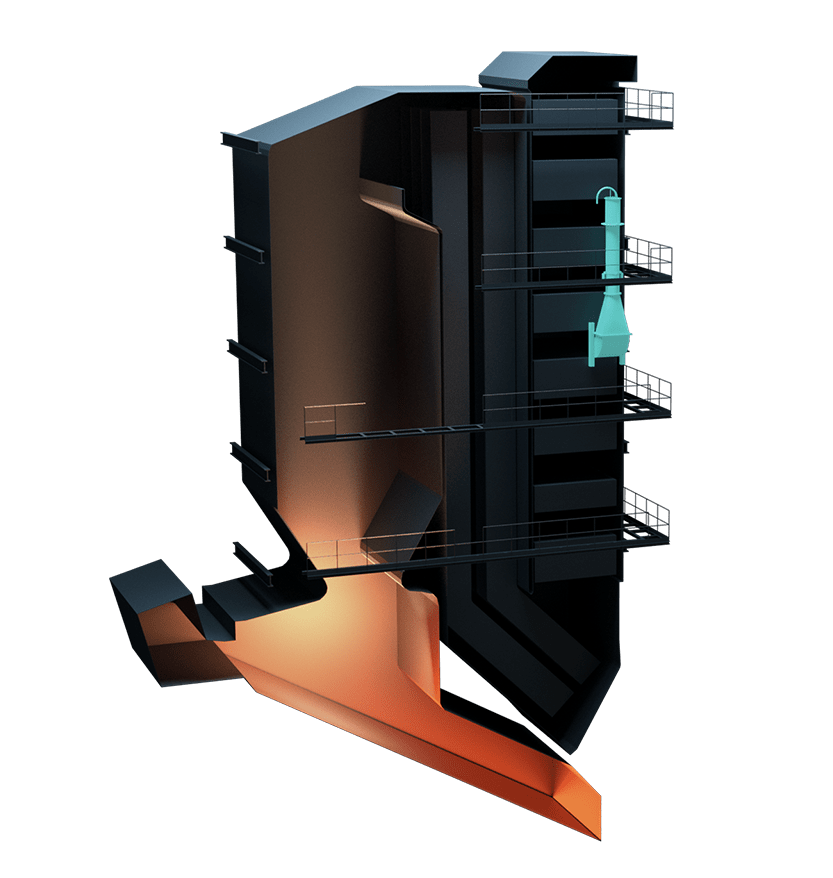

Waste to energy boiler

Waste-to-energy plants turn waste into valuable energy and minimize the need for landfilling

General info

Waste to energy boiler process

Waste to energy (WtE) is the process of creating energy in the form of electricity and/or heat from the incineration of waste. This type of fuel has a relatively high tendency to create fouling in all parts of the boiler.

About cleaning

Soot cleaning systems for Waste to energy boilers

Infrasound sonic cleaning offers a cost-effective and efficient greentech solution for preventing soot accumulation in boilers, thus reducing the need for conventional soot cleaning systems that wear on heat exchangers and require lots of maintenance. Typical applications for infrasound cleaning system on waste incinerators are Economizer and SCR. For our optimization of soot blowers, HISS™, all retractable steam soot blowers are targets for optimization, saving steam or e.g. improving steam data by soot blowing more often in problematic areas, without increasing the total steam consumption of the soot blowers.

Benefits

Benefits our cleaning systems brings to the customer are:

Reduced or eliminated steam consumption for steam soot blowing. Increased production or reduced need for auxiliary boilers.

Reduced or eliminated need of shot cleaning. Reduced or eliminated operational and maintenance costs of the shot cleaning system.

Increased lifetime of heat exchangers. Non-abrasive infrasound cleaning increases the lifetime of heat exchangers by reducing the need for conventional cleaning systems. Infrasound cleaning does not contribute to corrosion or erosion of heat exchangers. Our optimization of soot blowers reduced steam consumption and tube wear by 50 %.

Lower and more stable differential pressure. Infrasound cleaning reaches areas that not accessible to conventional soot cleaning systems.

Fewer outages for manual cleaning. Increased availability and energy production.