A new way for industries

In the face of escalating environmental concerns and the push for greater operational efficiency, Heat Management presents pioneering solutions that don’t just promise, but deliver substantial efficiency improvements for pulp mills.

Explore how our patented technologies, including HISS™ and Infrasound Cleaning, are setting new standards in industrial performance and ecological stewardship across North America.

A new way

for industries

for industries

In the face of escalating environmental concerns and the push for greater operational efficiency, Heat Management presents pioneering solutions that don’t just promise, but deliver substantial efficiency improvements for pulp mills.

Explore how our patented technologies, including HISS™ and Infrasound Cleaning, are setting new standards in industrial performance and ecological stewardship across North America.

Key results

Our customers have increased their black liquor throughput by 7-12% and have reduced their sootblowing steam consumption by up to 40%. Learn more

Talk to our expert

Do you want to learn more about what we can do for your mill. Book a meeting with our Sales Manager Andreas Aspell.

BOOK A MEETING

Key results

Our customers have increased their black liquor throughput by 7-12% and have reduced their sootblowing steam consumption by up to 40%. Learn more.

Do you want to learn more about what Heat Management can do for your mill. Book a meeting with our Sales Manager Andreas Aspell.

BOOK A MEETING

What do we solve

Reduced environmental impact

Dramatically lower your carbon footprint with our cleaning solutions.

Operational efficiency

Boost your plant’s efficiency, reducing downtime and maintenance costs.

Cost savings

Achieve significant savings on energy and operational expenses, driving profitability.

What do we solve

Reduced environmental impact:

Dramatically lower your carbon footprint with our cleaning solutions.

Operational efficiency

Boost your plant’s efficiency, reducing downtime and maintenance costs.

Cost savings

Achieve significant savings on energy and operational expenses, driving profitability.

Success stories

Join industry leaders who trust Heat Management. Pulp mills like Zelstoff Pöls in Austria have reduced the sootblowing steam consumption by 36-41% after HISS installation. Aspa Mill in Sweden has its sootblowers running at 200%, reducing the number of explosion cleanings by 50%. Read more about our customer cases below.

Zellstoff Pöls, Austria

In 2020, Zellstoff Pöls AG made the investment to commission a sootblowing solution that were to be installed on all 86 of their sootblowers. The project evaluation has now been finalized and it revealed incredible results.

DOWNLOAD THE CUSTOMER CASE

BillerudKorsnäs Gruvön, Sweden

After performing a boiler operation study at BillerudKorsnäs Gruvön, it was obvious that substantial savings could be obtained from reducing sootblower steam consumption and at the same time operating the steam sootblower more often for handling fouling at the heat transfer surfaces of the boiler.

DOWNLOAD THE CUSTOMER CASE

Södra Cell Värö, Sweden

In 2020 Södra Cell Värö initiated the Expansion 2.0 project, to increase production from 710 000 ADMT/year of NBSK pulp to 780 000 ADMT/year. The identified bottleneck was the recovery boiler. HISS(TM) was installed to increase the online cleaning capacity and to maintain high availability at the continuous load of 4 800 tDS/day without rebuilding the boiler. The boiler design load is 4 200 tDS/day.

DOWNLOAD THE CUSTOMER CASE

Ahlström-Munksjö Aspa Bruk, Sweden

The goal with the HISS project at Ahlström-Munksjö Aspa Bruk was to run the boiler at maximum load and increase the cleaning effect in the boiler with maintained steam consumption. The problems with plugging in the Superheater and the Boiler Bank created a need for frequent explosion cleaning.

DOWNLOAD THE CUSTOMER CASE

Success stories

Join industry leaders who trust Heat Management. Pulp mills like Zelstoff Pöls in Austria have reduced the sootblowing steam consumption by 36-41% after HISS installation. Aspa Mill in Sweden has its sootblowers running at 200%, reducing the number of explosion cleanings by 50%. Read more about our customer cases below.

Zellstoff Pöls, Austria

In 2020, Zellstoff Pöls AG made the investment to commission a sootblowing solution that were to be installed on all 86 of their sootblowers. The project evaluation has now been finalized and it revealed incredible results.

BillerudKorsnäs Gruvön, Sweden

After performing a boiler operation study at BillerudKorsnäs Gruvön, it was obvious that substantial savings could be obtained from reducing sootblower steam consumption and at the same time operating the steam sootblower more often for handling fouling at the heat transfer surfaces of the boiler.

Södra Cell Värö, Sweden

In 2020 Södra Cell Värö initiated the Expansion 2.0 project, to increase production from 710 000 ADMT/year of NBSK pulp to 780 000 ADMT/year. The identified bottleneck was the recovery boiler. HISS(TM) was installed to increase the online cleaning capacity and to maintain high availability at the continuous load of 4 800 tDS/day without rebuilding the boiler. The boiler design load is 4 200 tDS/day.

Ahlström-Munksjö Aspa Bruk, Sweden

The goal with the HISS project at Ahlström-Munksjö Aspa Bruk was to run the boiler at maximum load and increase the cleaning effect in the boiler with maintained steam consumption. The problems with plugging in the Superheater and the Boiler Bank created a need for frequent explosion cleaning.

“In the final evaluation of the HISS™ system, we have been able to measure results that with a good margin supersedes the guaranteed values, making it easier to reach sustainability goals while also taking our production of renewable power to new lengths”.

Christian Perschler, Project Manager for Zellstoff Pöls

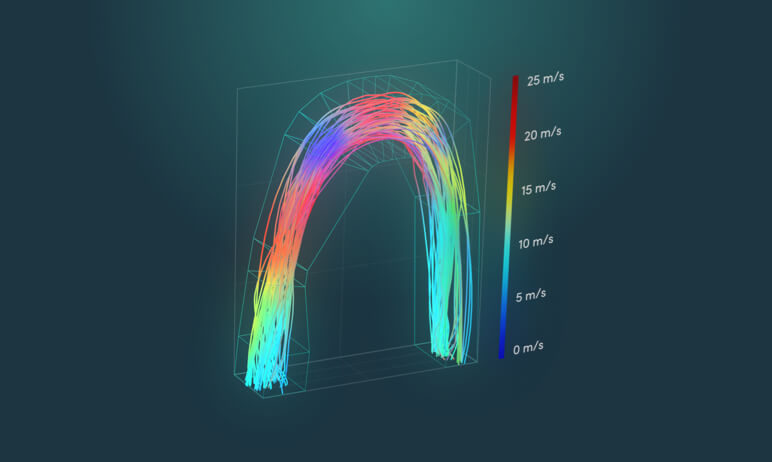

How it works

Our technology integrates seamlessly into your existing operations. The HISS™ system optimizes steam sootblowing processes, while Infrasound Cleaning maintains cleanliness without interrupting your workflow. This dual approach ensures maximum efficiency and sustainability.

Our solutions

How it works

Our technology integrates seamlessly into your existing operations. The HISS™ system optimizes steam sootblowing processes, while Infrasound Cleaning maintains cleanliness without interrupting your workflow. This dual approach ensures maximum efficiency and sustainability.