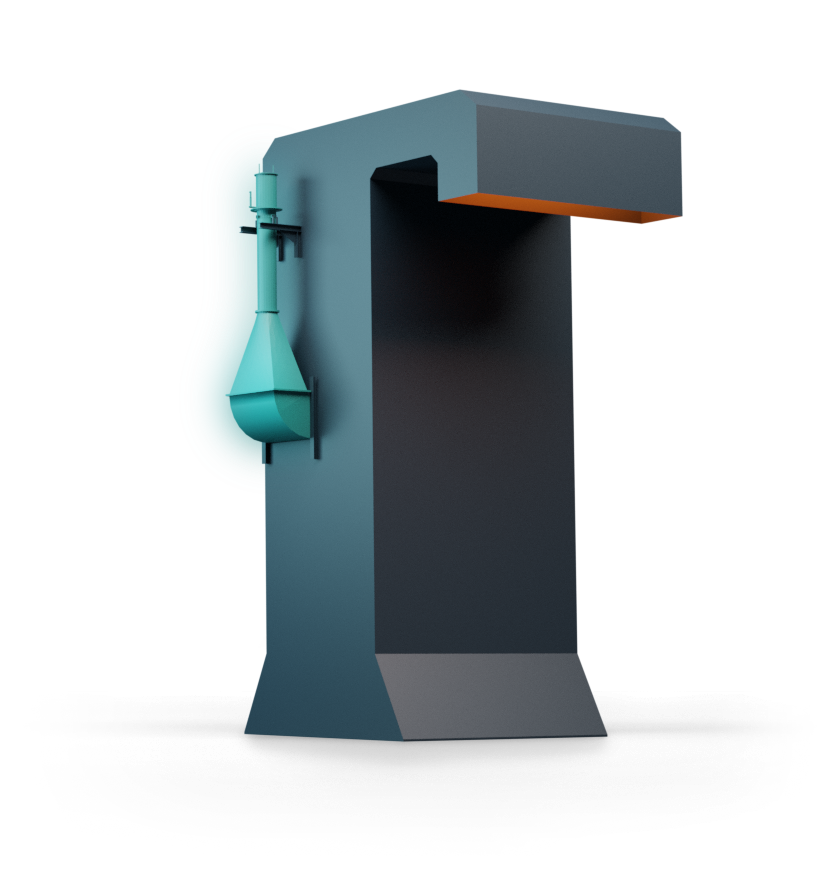

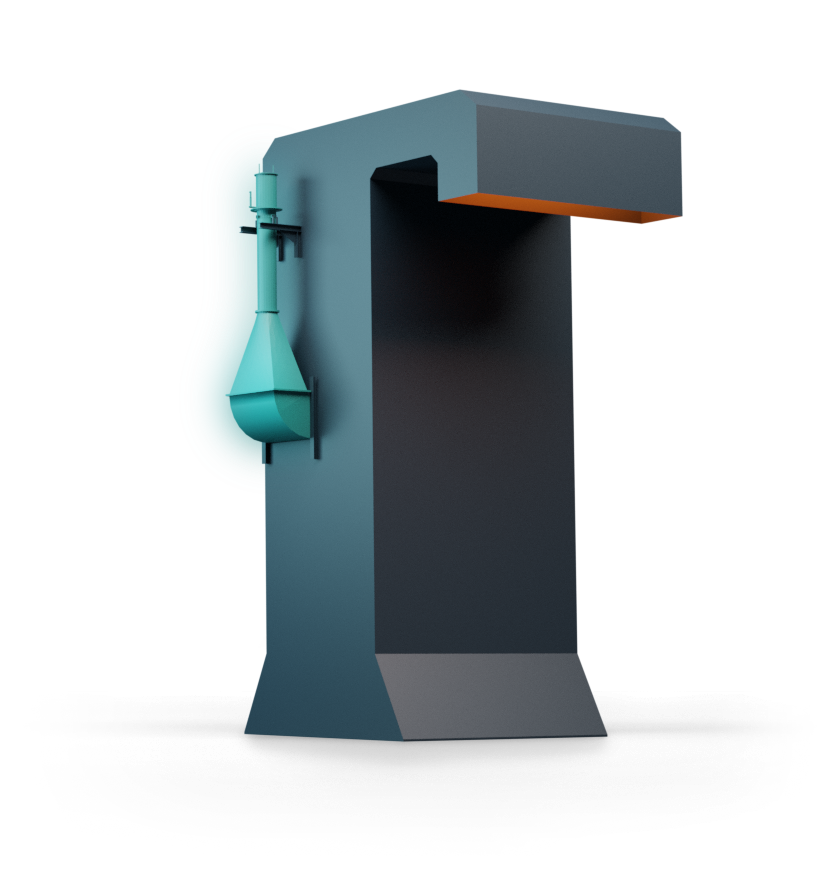

SCR – Selective Catalytic Reduction

SCRs are found in all industrial applications where NOx is regulated, most common in coal-, waste-, gas- and biomass-fired utilities as well as cement applications.

General info

The SCR system is a flue gas filter

The SCR system is a flue gas filter installed in the gas duct, upstream the stack. Inside of the SCR are hundreds of thousands of catalyst coated channels, where the gas passes through. Inside the channels, the catalyst promotes NOx molecules to react with ammonia injected upstream the SCR, to form harmless Nitrogen and water. For the reaction to occur, the surface of the channels needs to be kept clean however during operation, particles from the combustion process tend to adhere to the catalyst surface, preventing said reactions.

After some time of operation, whole channels are plugged with particles, creating a pressure drop and prompting the flue gas to flow with higher velocities through the remaining open channels. This reduces the efficiency of the SCR, increases the consumption of Ammonia and can also errode the catalyst, leading to costly replacements.

About cleaning

Automatic, on-line cleaning of SCR

Heat Management employs an automatic, non-abrasive cleaning method to prevent plugging inside of the catalyst channels. The solution developed and patented by Heat Management harnesses the long range, omni-directional turbulence generated by non-audible sound, to efficiently and preventively keep the channels open.

The solution works by disturbing the laminar flow inside each and everyone of the channels, at the same time and with the same intensity for a few seconds every couple of minutes. Results are stabilized gas differential pressures and Ammonia slip levels and increased catalyst lifetime, reducing the cost of ownership of the SCR system.